A Global Network: Exploring the Toyota and Mazda Manufacturing Landscape

Related Articles: A Global Network: Exploring the Toyota and Mazda Manufacturing Landscape

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to A Global Network: Exploring the Toyota and Mazda Manufacturing Landscape. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A Global Network: Exploring the Toyota and Mazda Manufacturing Landscape

The automotive industry is a global enterprise, with manufacturers establishing production facilities across the world to meet diverse market demands and optimize production costs. Toyota and Mazda, two prominent Japanese automotive manufacturers, have strategically established a network of manufacturing plants spanning multiple continents. This intricate global network is a testament to their commitment to global market penetration and efficient production.

Understanding the Geographic Distribution of Toyota and Mazda Plants

To effectively understand the global reach of Toyota and Mazda, it is crucial to analyze the location of their manufacturing plants. This analysis provides insights into their strategic considerations, market targeting, and overall manufacturing footprint.

Toyota’s Manufacturing Footprint

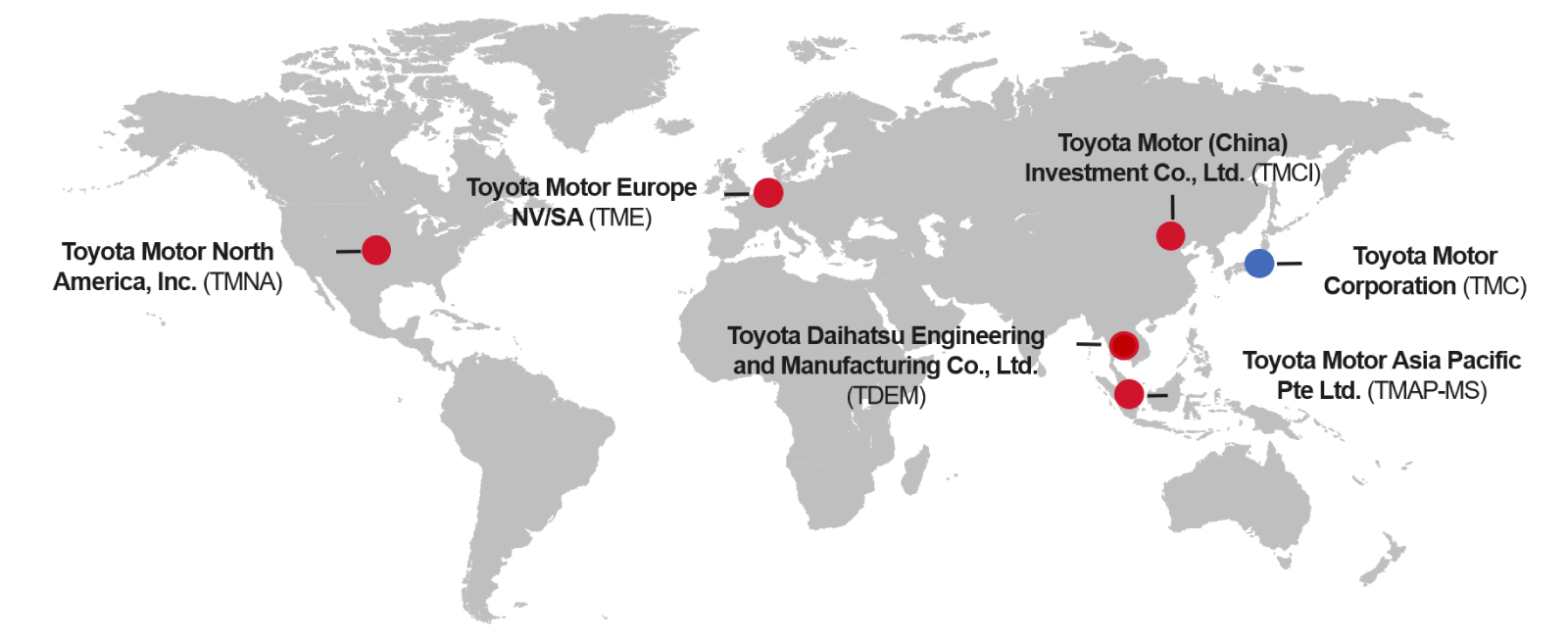

Toyota, a global automotive leader, operates a vast network of manufacturing plants across the globe. These plants are strategically located to cater to regional market demands, leverage local resources, and optimize production costs.

- North America: Toyota’s North American operations are centered in the United States, Canada, and Mexico. This region represents a significant market for Toyota, with plants in key states like Kentucky, Indiana, Texas, and California.

- South America: Toyota’s presence in South America is limited to Brazil, where it operates a single plant in Sao Paulo. This strategic location allows Toyota to tap into the growing South American market.

- Europe: Toyota’s European operations are spread across France, the United Kingdom, and the Czech Republic. These plants cater to the European market, with a focus on hybrid and electric vehicle production.

- Asia: Toyota’s Asian operations are extensive, with plants in Japan, China, Thailand, Indonesia, Malaysia, and other Southeast Asian countries. This region represents a significant production hub for Toyota, with a focus on manufacturing vehicles for both domestic and export markets.

- Africa: Toyota’s African operations are centered in South Africa, where it operates a single plant in Durban. This strategic location allows Toyota to leverage the growing African market.

Mazda’s Manufacturing Footprint

Mazda, another prominent Japanese automotive manufacturer, has a more focused manufacturing network compared to Toyota. While Mazda’s global reach is smaller, it maintains a significant presence in key markets.

- North America: Mazda’s North American operations are centered in the United States, with a single plant in Flat Rock, Michigan. This plant focuses on producing vehicles for the North American market.

- Europe: Mazda’s European operations are limited to a single plant in Hofu, Japan, which exports vehicles to the European market.

- Asia: Mazda’s Asian operations are centered in Japan, with plants in Hiroshima, Hofu, and Yamaguchi. These plants cater to the domestic market and export vehicles to other regions.

- Australia: Mazda operates a single plant in Australia, located in Broadmeadows, Victoria. This plant caters to the Australian market and exports vehicles to other regions.

Benefits of Toyota and Mazda’s Global Manufacturing Network

The geographically diverse manufacturing network of Toyota and Mazda offers several significant benefits:

- Market Proximity: By establishing plants in key markets, Toyota and Mazda can reduce transportation costs and delivery times, allowing them to respond quickly to market fluctuations and customer demands.

- Local Sourcing and Employment: Manufacturing facilities create local jobs and contribute to the economic growth of the region. Additionally, sourcing components from local suppliers reduces transportation costs and promotes regional economic development.

- Diversification and Risk Mitigation: Having multiple plants across different regions helps mitigate risks associated with political instability, natural disasters, or economic downturns in a specific region.

- Flexibility and Adaptability: A global network allows Toyota and Mazda to adapt to changing market trends and consumer preferences, enabling them to introduce new models and technologies quickly.

Challenges and Considerations in Global Manufacturing

While the benefits of a global manufacturing network are undeniable, it also presents several challenges:

- Logistics and Transportation Costs: Managing a global network requires efficient logistics and transportation systems, which can be complex and costly.

- Political and Economic Risks: Operating in different countries exposes manufacturers to political instability, currency fluctuations, and trade barriers.

- Cultural and Language Barriers: Communicating and collaborating effectively across diverse cultures and languages can be challenging.

- Environmental Regulations and Sustainability: Each country has its own environmental regulations and sustainability standards, which manufacturers must comply with.

Toyota and Mazda’s Collaborative Ventures: A New Era of Manufacturing

In recent years, Toyota and Mazda have embarked on collaborative ventures to enhance their manufacturing capabilities and address evolving market trends. One notable example is the joint venture to build a new plant in Huntsville, Alabama, which is expected to produce vehicles for both brands. This partnership leverages the strengths of both companies, allowing them to share resources, technology, and expertise.

FAQs Regarding Toyota and Mazda Plant Locations

1. What is the primary reason for Toyota and Mazda’s global manufacturing network?

The primary reason is to cater to regional market demands, optimize production costs, and leverage local resources. This strategy allows them to respond quickly to market fluctuations and customer preferences.

2. What are the key regions where Toyota and Mazda have manufacturing plants?

Toyota and Mazda have a global presence, with plants in North America, South America, Europe, Asia, and Africa. They focus on key markets with strong demand for their vehicles.

3. How do Toyota and Mazda’s manufacturing strategies differ?

Toyota has a more extensive global network with plants in more regions, while Mazda has a more focused approach with a smaller number of plants.

4. What are the benefits of Toyota and Mazda’s collaborative ventures?

Collaborative ventures allow Toyota and Mazda to share resources, technology, and expertise, leading to enhanced manufacturing capabilities and increased efficiency.

5. What are the challenges associated with global manufacturing?

Challenges include logistics and transportation costs, political and economic risks, cultural and language barriers, and compliance with diverse environmental regulations.

Tips for Understanding Toyota and Mazda Plant Locations

- Utilize online resources: Websites like Wikipedia, Toyota’s official website, and Mazda’s official website provide detailed information on plant locations and production capacities.

- Explore interactive maps: Many online resources offer interactive maps that display plant locations and production volumes.

- Consult industry reports: Industry reports and publications often provide insights into the automotive manufacturing landscape, including plant locations and production trends.

- Follow industry news: Staying informed about industry news and developments can help you understand the latest changes in plant locations and production strategies.

Conclusion

Toyota and Mazda’s global manufacturing network is a testament to their commitment to meeting diverse market demands and optimizing production costs. By strategically establishing plants in key regions, they leverage local resources, contribute to economic growth, and respond quickly to market changes. While challenges exist, their commitment to innovation and collaboration paves the way for continued success in the ever-evolving automotive industry.

Closure

Thus, we hope this article has provided valuable insights into A Global Network: Exploring the Toyota and Mazda Manufacturing Landscape. We appreciate your attention to our article. See you in our next article!